In the world of manufacturing, few processes are as transformative and precise as CNC machining. Short for Computer Numerical Control, this innovative technique has revolutionized the way we create everything from intricate parts for aerospace engineering to custom furniture.

But what exactly does CNC machining entail? Imagine a dance between high-tech machinery and meticulous programming, where each movement is choreographed with the utmost precision. It’s not just about cutting materials; it’s about bringing visions to life with stunning accuracy and efficiency.

Whether you’re an aspiring engineer, a hobbyist, or simply curious about modern manufacturing, this guide will take you through the fundamental concepts, techniques, and applications of CNC machining, shedding light on why its a cornerstone of today’s industry. Prepare to embark on a journey that uncovers the fascinating interplay of creativity and technology in the realm of CNC machining.

The Basics of CNC Technology

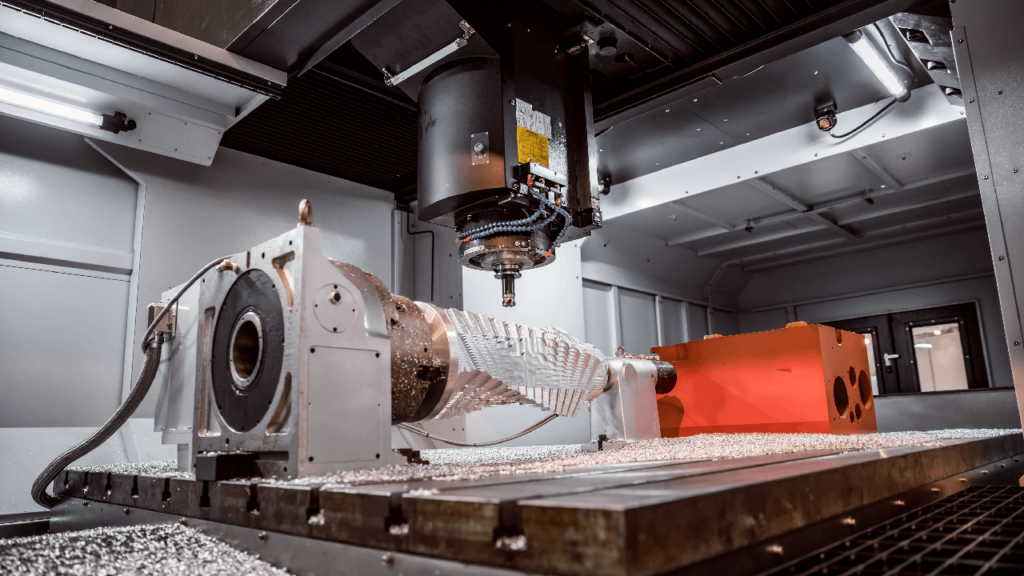

CNC technology, or Computer Numerical Control, is a revolutionary method that employs computer software to direct machine tools in the manufacturing process. At its core, CNC transforms raw materials—metal, wood, plastic—into precision-engineered components by interpreting intricate digital designs. These machines operate according to coded instructions, allowing for remarkable accuracy and repeatability. Imagine a leading-edge lathe or a milling machine, executing complex patterns that would be nearly impossible to achieve manually.

This level of automation not only enhances productivity but also reduces human error, making it an essential tool in modern fabrication. To leverage these capabilities, many businesses turn to specialized cnc machining service, which provide the expertise and technology needed to bring precise designs to life. As you dive deeper into CNC machining, you’ll discover how this technology intersects artistry and engineering, opening doors to endless possibilities for innovation and design.

Different Types of CNC Machines

CNC machines come in various shapes and sizes, each designed to cater to different manufacturing needs and materials. The most common type, CNC milling machines, utilize rotary cutters to carve out complex shapes from solid blocks of material, while CNC lathes rotate the workpiece against a stationary cutting tool to create cylindrical components.

Laser cutters, another popular option, use focused beams of light to cut or engrave intricate designs with remarkable precision, making them perfect for delicate materials. Plasma cutters harness high-temperature plasma to slice through thick metal sheets, providing speed and efficiency for heavy-duty applications.

Then there are CNC routers, designed mainly for woodworking and softer materials, capable of providing detailed carvings and intricate designs. Each technology, with its unique strengths, offers manufacturers remarkable flexibility and creativity in the ever-evolving world of CNC machining.

Common Applications of CNC Machining

CNC machining finds its way into a myriad of industries, showcasing its versatility and precision. From the intricate world of aerospace manufacturing, where components must withstand extreme conditions, to the robust requirements of automotive production, CNC technology ensures that parts are crafted with unparalleled accuracy.

Imagine medical devices, where even the slightest error can have serious implications; here, CNC machining plays a critical role in producing life-saving instruments that adhere to stringent regulations. The world of furniture design also benefits, as CNC machines carve out elaborate and unique designs, merging art with functionality.

Additionally, the rapid prototyping sector harnesses CNC capabilities to bring innovative ideas to life at astounding speeds, allowing for quick adjustments and iterations. This diverse array of applications underscores the importance of CNC machining in modern manufacturing and design, bridging the gap between creativity and precision engineering.

Conclusion

In conclusion, CNC machining is a revolutionary manufacturing process that transforms raw materials into precisely crafted components, making it an essential technique in various industries. With its ability to enhance efficiency, improve accuracy, and reduce waste, understanding CNC machining can open up numerous opportunities for both seasoned professionals and beginners alike.

For those looking to leverage this technology without the overhead of in-house machinery, turning to a reliable CNC machining service can provide tailored solutions to meet specific needs. By appreciating the fundamentals of CNC machining, individuals and businesses can harness its capabilities to drive innovation and achieve outstanding results in their projects.